Our Services

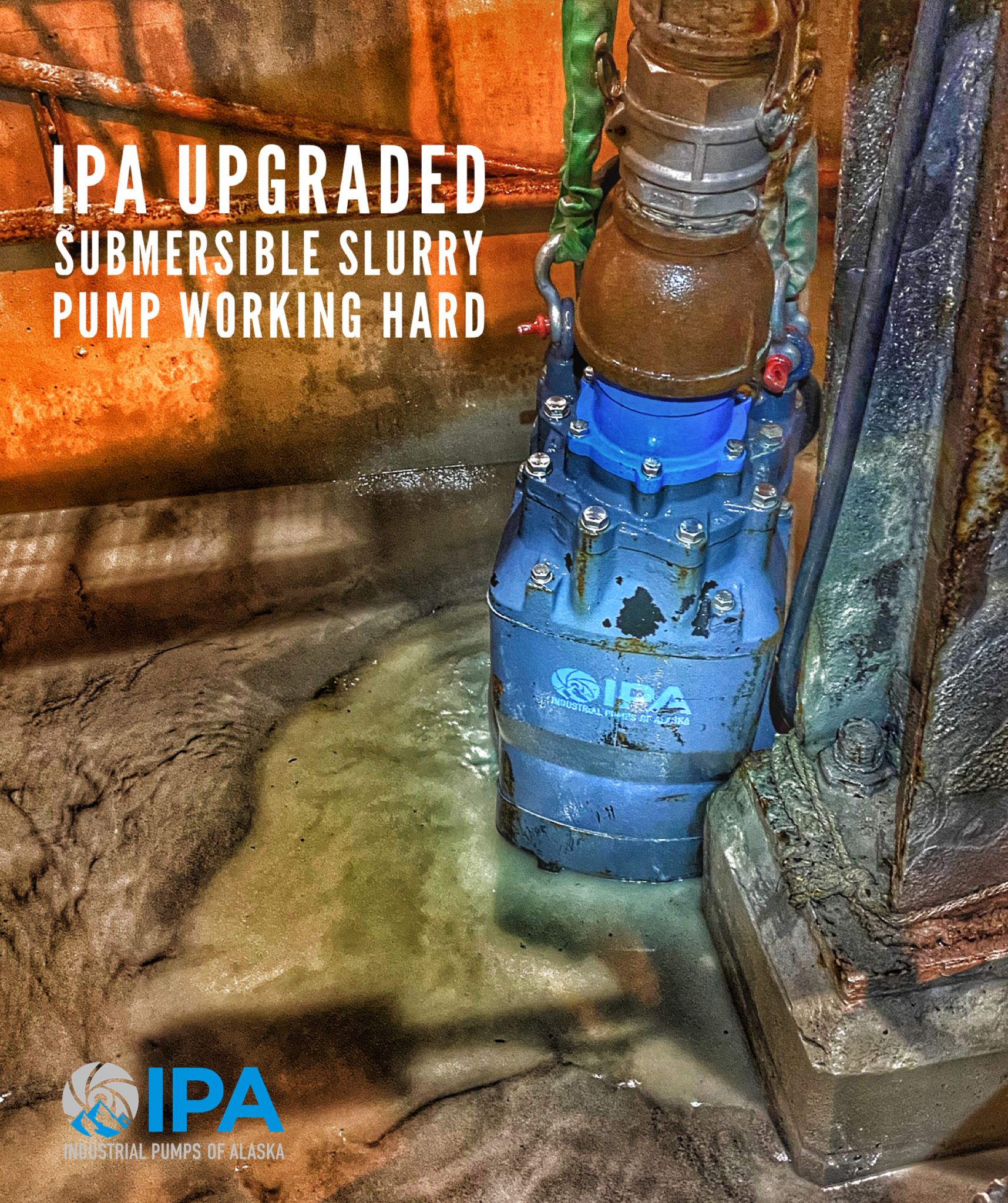

Pump Service

Industrial pump service involves the maintenance, repair, and optimization of pumps used in various industrial processes. This service ensures that pumps operate efficiently, minimizing downtime and maximizing productivity for industries such as manufacturing, water treatment, and oil and gas.

Installations

Pump installations encompass the process of setting up pumps within industrial facilities or systems. This involves careful planning, precise positioning, and connection to relevant piping or infrastructure. Proper installation ensures optimal performance and longevity of the pumping system, meeting the specific requirements of the industry.

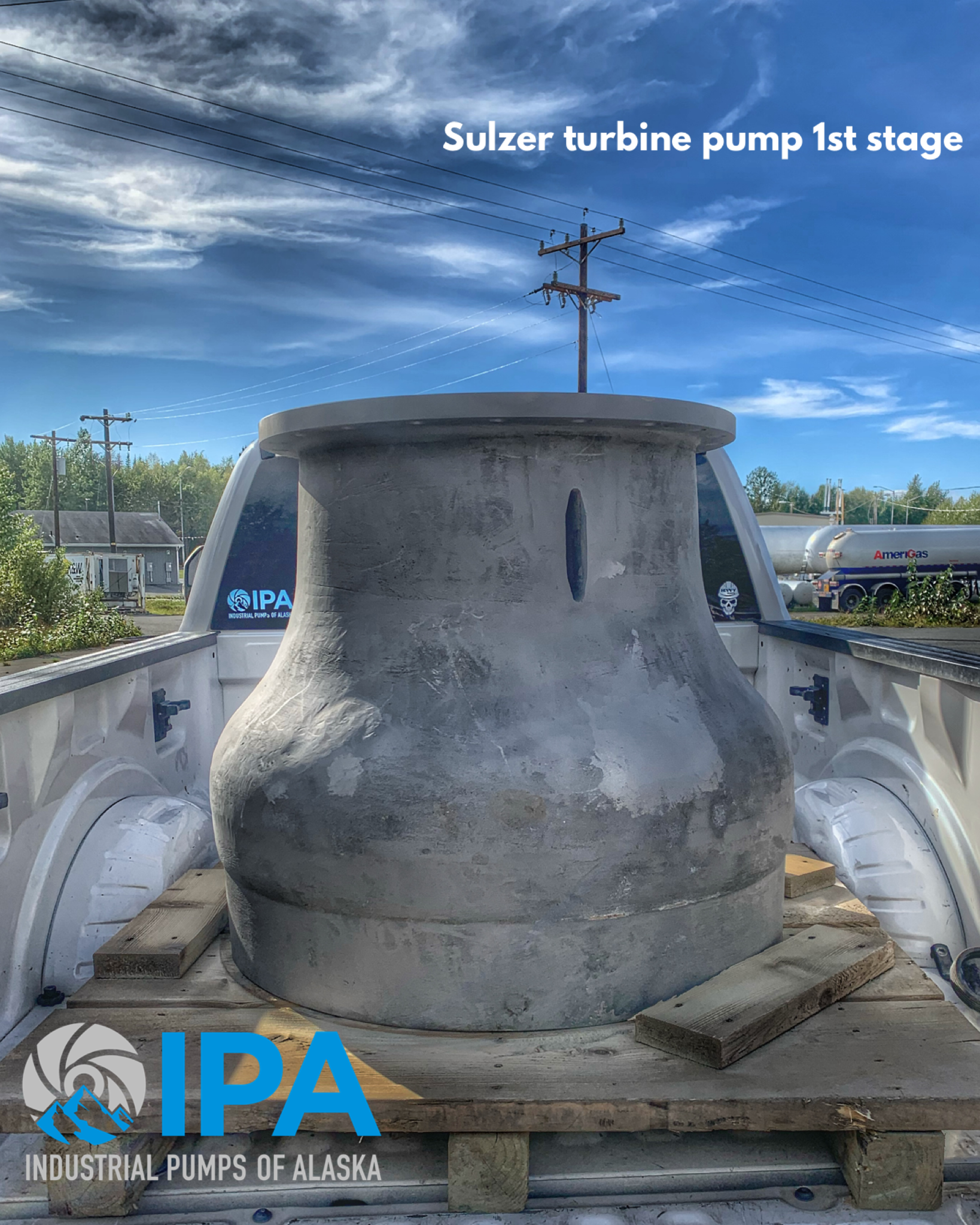

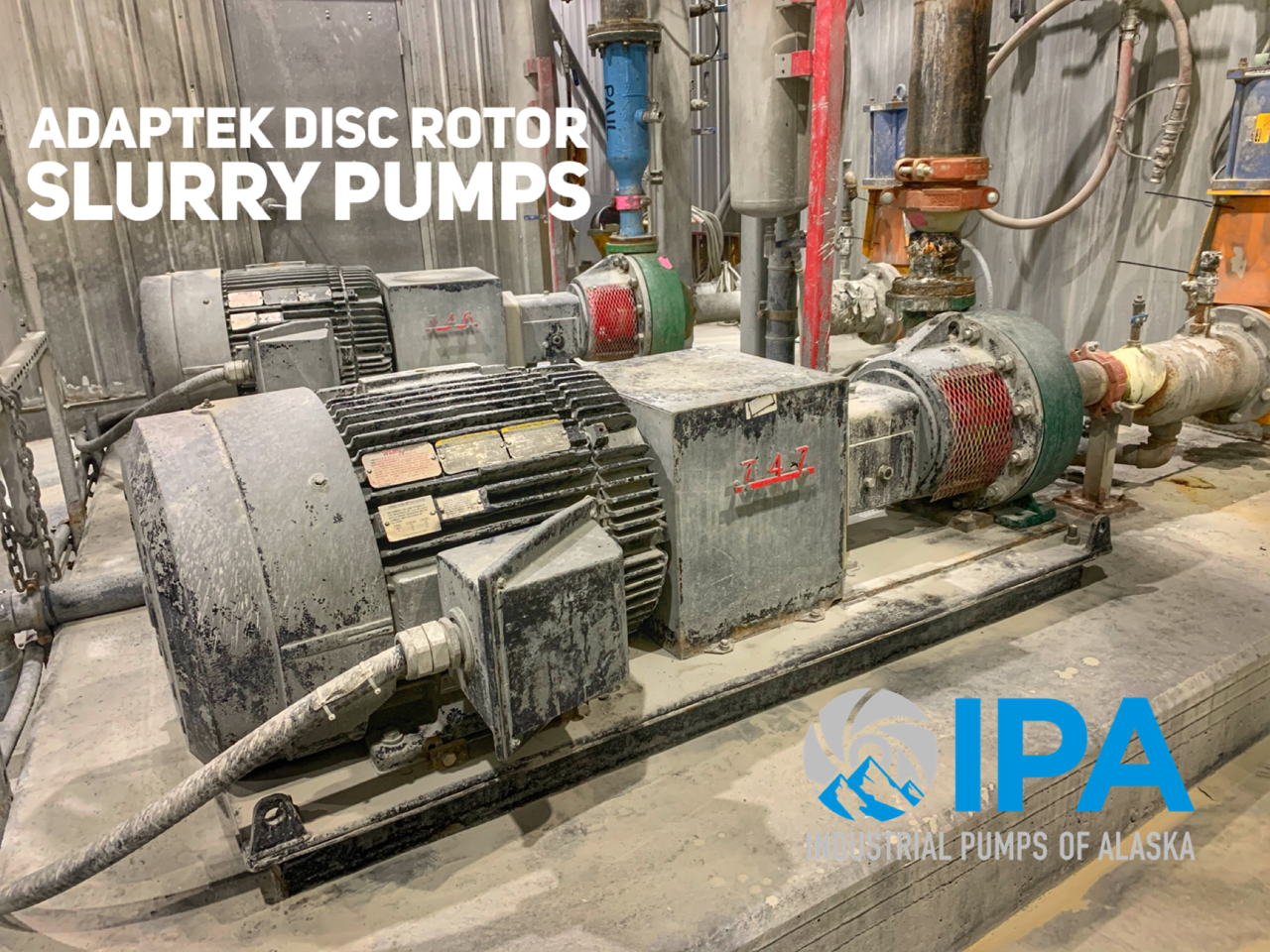

Sales

Pump sales involve the distribution and provision of various types of pumps to industrial clients. Sales professionals in this field typically assess the needs of customers, recommend suitable pump solutions, negotiate terms, and facilitate transactions. They may offer a range of pump types, including centrifugal, diaphragm, and submersible pumps, tailored to the client's applications.

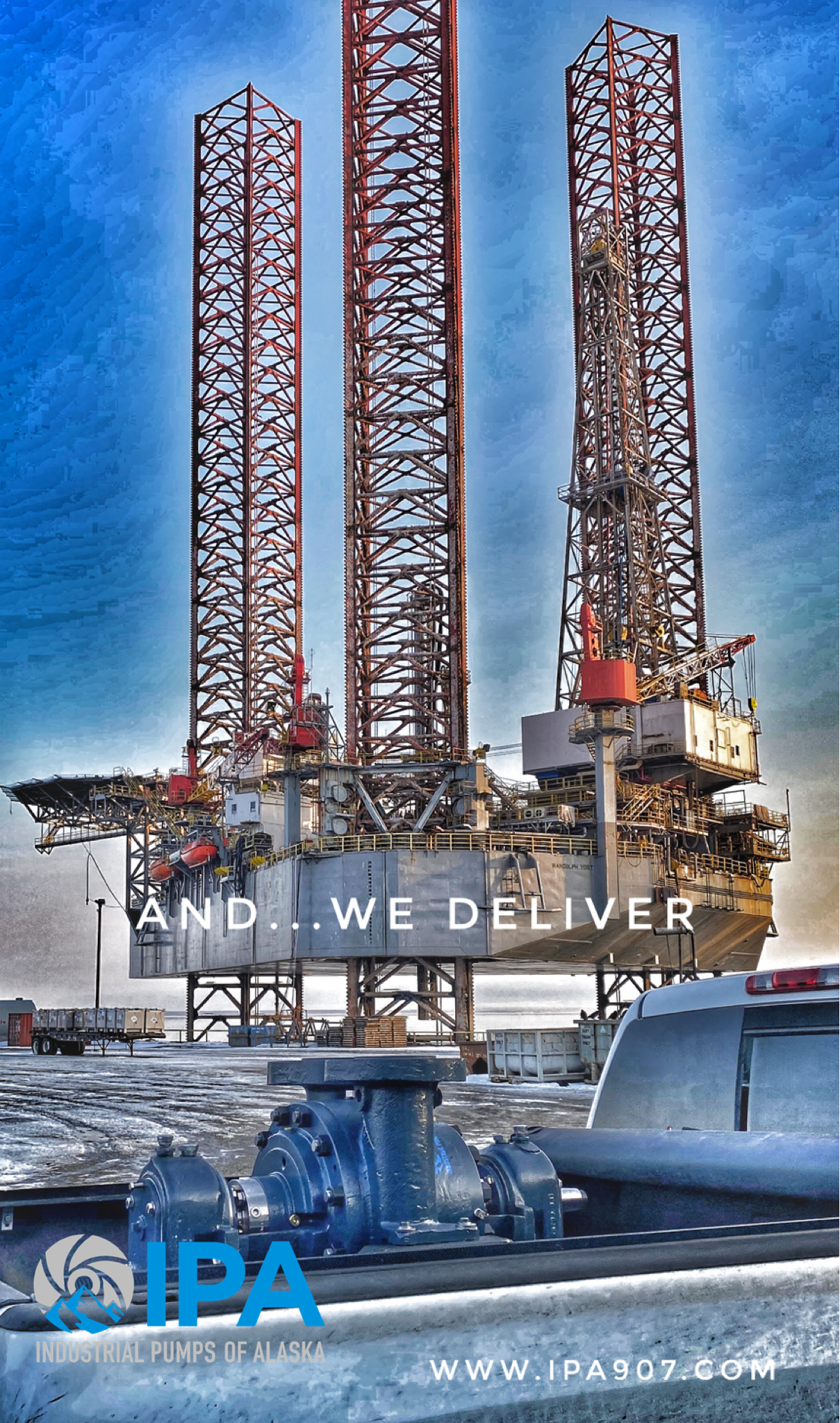

Field Service

Field service refers to on-site support and assistance provided for industrial pump systems. Field service technicians are tasked with troubleshooting issues, performing repairs or maintenance, and offering technical expertise directly at the client's location. This service ensures quick response times and minimizes disruptions to industrial operations.

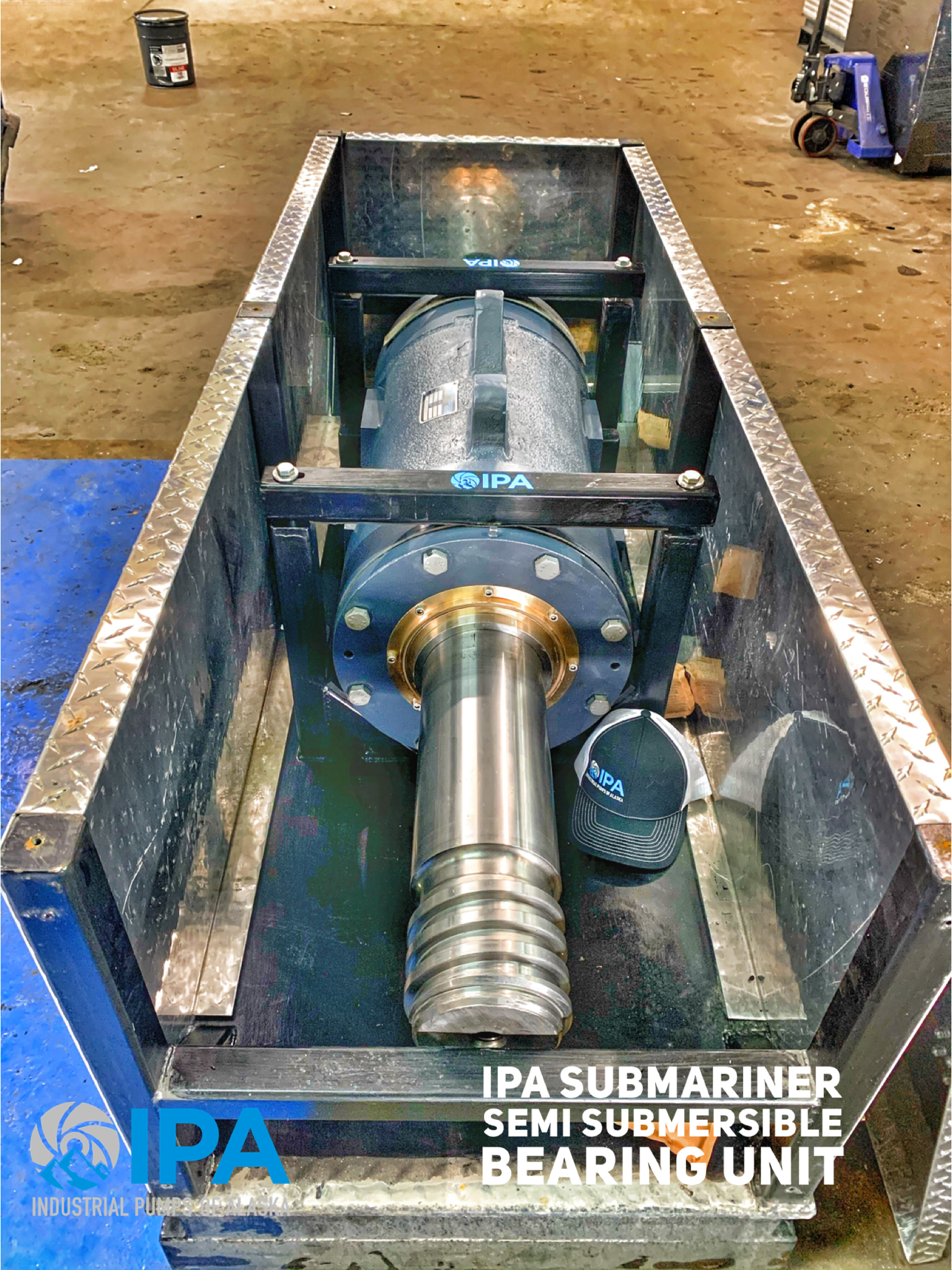

Engineering

Pump engineering involves the design, development, and optimization of pump systems to meet specific industrial requirements. Pump engineers utilize principles of fluid dynamics, thermodynamics, and mechanical engineering to create efficient and reliable pumping solutions. They may also engage in research and innovation to improve pump performance, energy efficiency, and sustainability.