Choosing the Best Pumps for Cold Weather Performance in Alaskan Industries

Daisy Wick • June 24, 2024

Choosing the Best Pumps for Cold Weather Performance in Alaskan Industries

Alaska's harsh climate and remote locations pose significant challenges for industries that rely on mechanical pumps. The frigid temperatures and demanding conditions require pumps that can perform reliably without frequent maintenance or failure. In this blog, we'll explore which pumps are best suited for cold weather performance and how they meet the needs of various Alaskan industries.

Gear Pumps: Precision and Durability in Cold Climates

1. Cold Weather Performance:

Gear pumps are known for their high efficiency and precision, which remain consistent even in cold temperatures. Their robust construction and fewer moving parts make them less susceptible to temperature-related issues.

2. Industrial Applications:

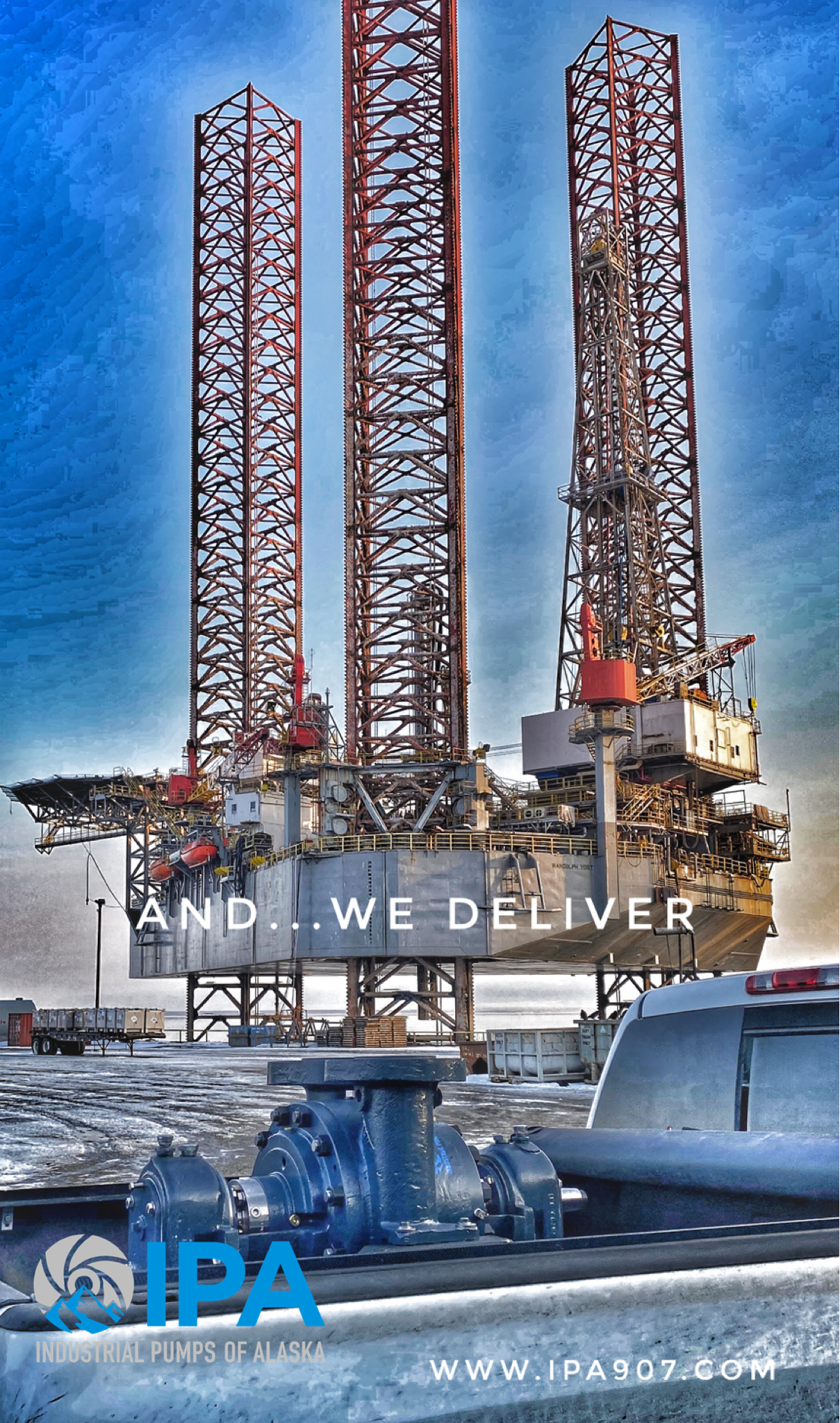

Oil and Gas: Gear pumps are widely used for transferring lubricating oils, fuels, and other viscous fluids. Their ability to maintain a steady flow rate is crucial for hydraulic systems and chemical processing.

Chemical Processing: In industries dealing with chemicals, gear pumps ensure the precise handling of various fluids without performance degradation.

3. Advantages:

Durability: Built to withstand high pressures and tough environments, gear pumps offer long-lasting performance.

Efficiency: They provide a consistent flow rate, which is essential for operations requiring precise fluid control.

Diaphragm Pumps: Versatility and Robustness in Extreme Conditions

1. Cold Weather Performance:

Diaphragm pumps excel in cold weather due to their ability to self-prime and run dry without damage. This makes them highly reliable in remote and harsh conditions where maintenance resources are limited.

2. Industrial Applications:

Water Treatment: Diaphragm pumps are used in dewatering, water treatment plants, and handling wastewater, ensuring reliable performance in freezing temperatures.

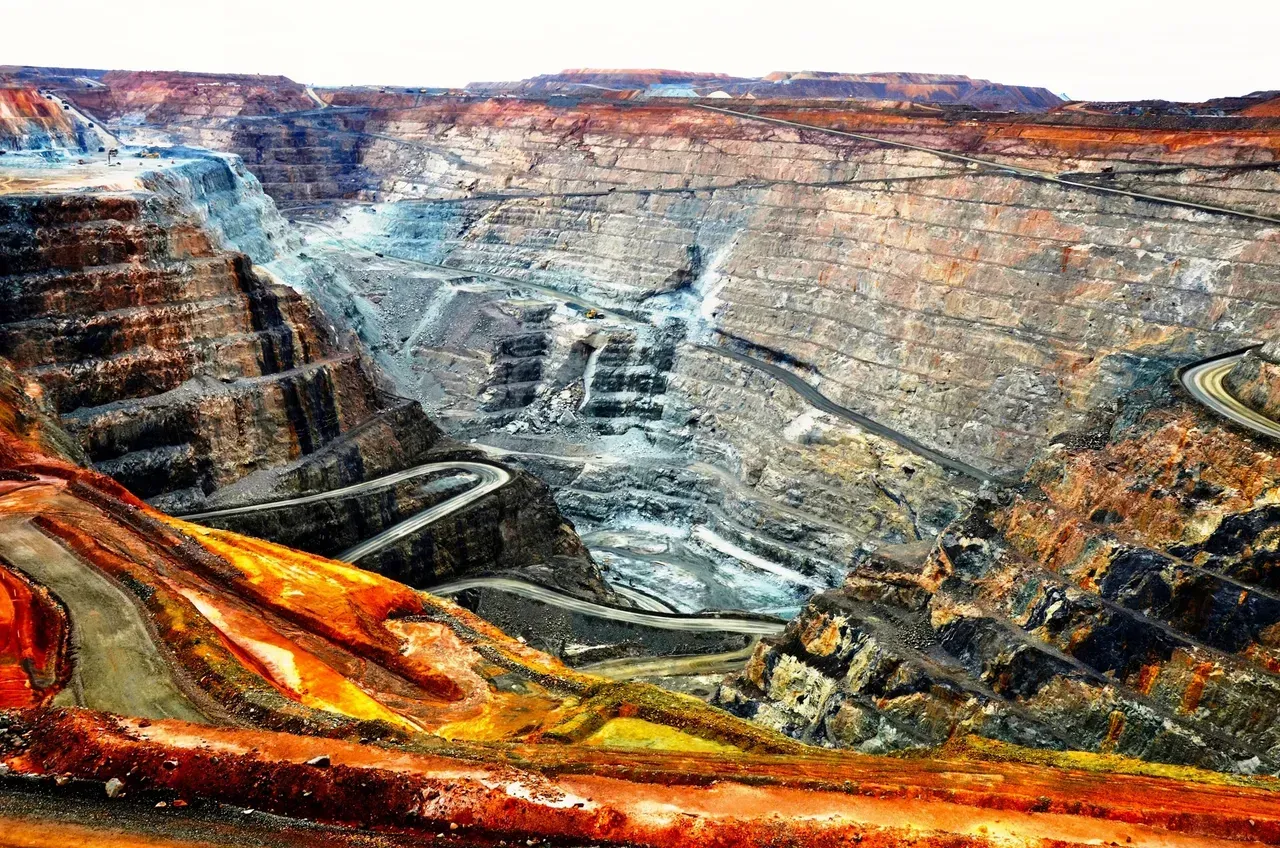

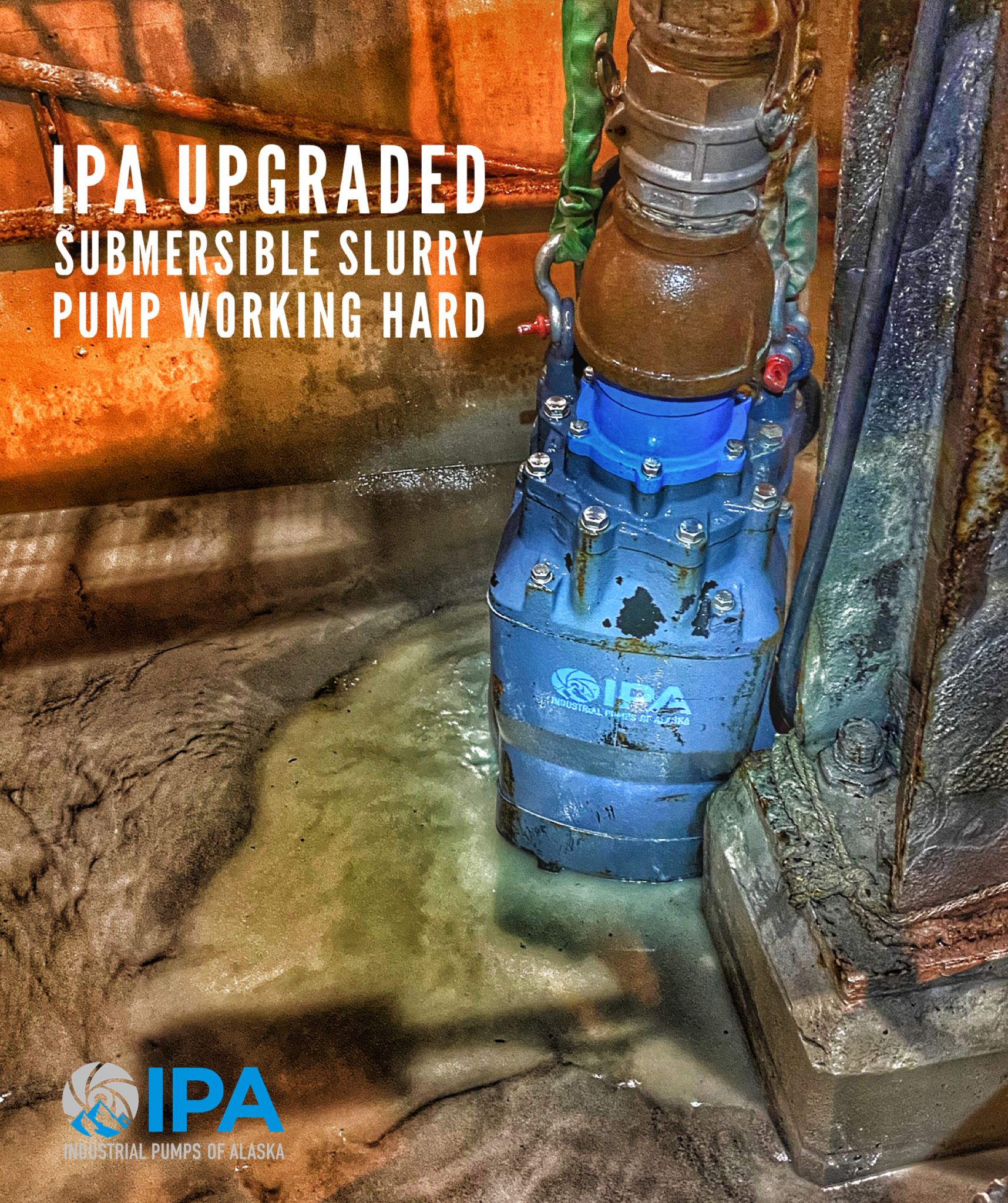

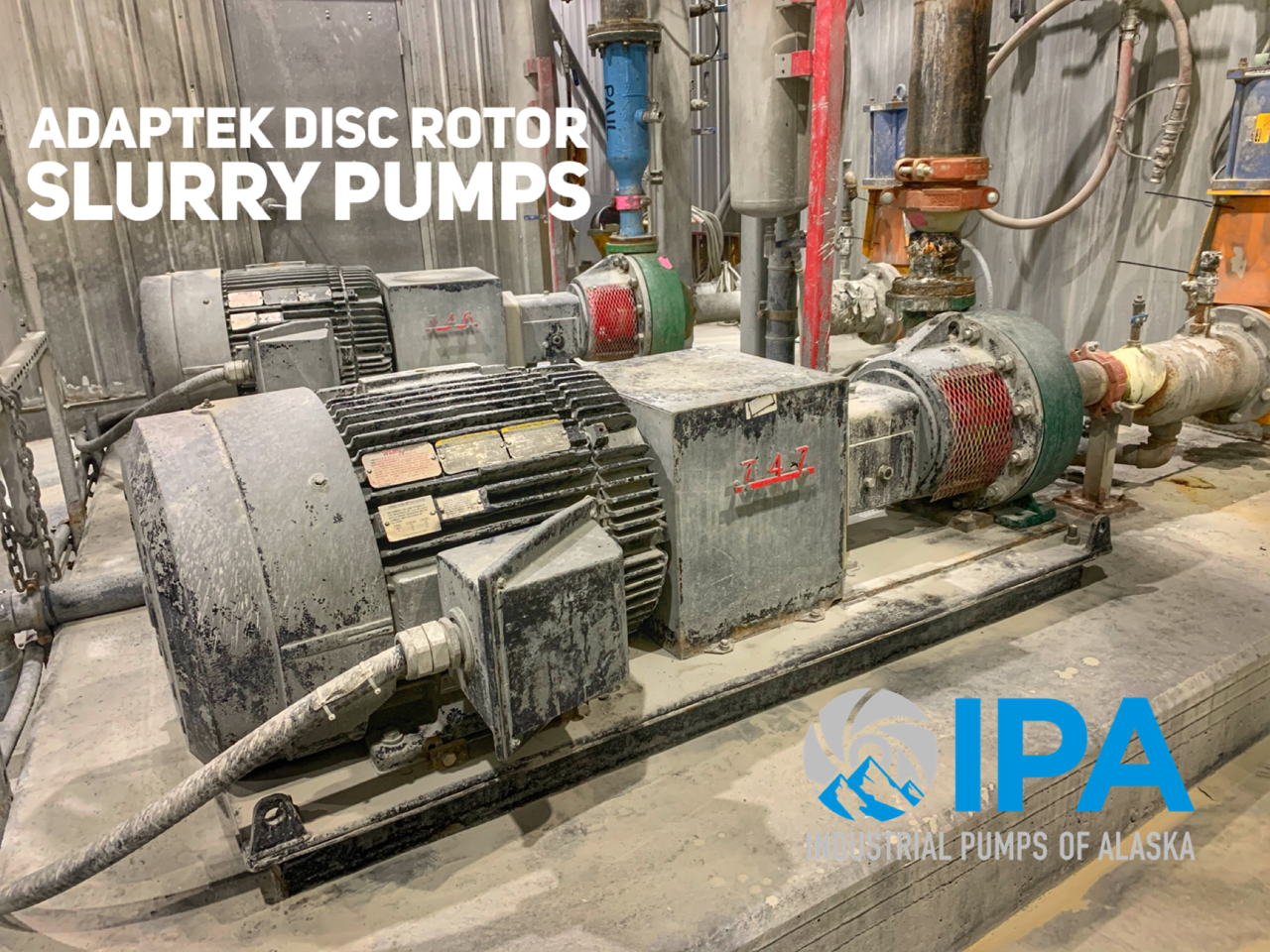

Mining: The mining industry in Alaska benefits from diaphragm pumps for slurry and sludge handling, where the ability to handle abrasive materials is crucial.

3. Advantages:

Self-Priming Capability: These pumps do not require manual priming, making them convenient for remote locations.

Solids Handling: Capable of pumping slurries and fluids with high solid content without clogging.

Corrosion Resistance: Suitable for handling aggressive chemicals and corrosive substances.

Peristaltic Pumps: Reliable and Low Maintenance

1. Cold Weather Performance:

Peristaltic pumps, with their sealed design and minimal moving parts, offer excellent reliability in cold weather. The pump’s tubing can be made from materials that remain flexible in low temperatures.

2. Industrial Applications:

Agriculture: Used for precise dosing of fertilizers and chemicals, ensuring efficient operation even in cold climates.

Food and Beverage: Ideal for hygienic applications where contamination must be avoided, functioning well in low-temperature environments.

3. Advantages:

Low Maintenance: With no valves, seals, or glands, these pumps require minimal maintenance.

Contamination-Free: The fluid only contacts the tubing, reducing the risk of contamination and making them suitable for sensitive applications.

Centrifugal Pumps: Adaptability with Proper Precautions

1. Cold Weather Performance:

Centrifugal pumps can be adapted for cold weather use with proper precautions, such as insulation and heat tracing to prevent freezing.

2. Industrial Applications:

Water Supply: Commonly used in water distribution systems, centrifugal pumps can be adapted to operate efficiently in cold climates with the right modifications.

Construction: Used for dewatering and other fluid transfer tasks on construction sites, provided they are adequately protected from freezing.

3. Advantages:

High Flow Rates: Centrifugal pumps are capable of moving large volumes of fluid efficiently.

Versatility: Suitable for a wide range of applications, including water supply and industrial fluid transfer.

Conclusion

When selecting pumps for use in Alaska's cold weather and demanding industry climates, it's essential to consider the specific needs of each application. Gear pumps offer precision and durability, making them ideal for the oil and gas sector. Diaphragm pumps provide versatility and robustness, perfect for water treatment and mining. Peristaltic pumps ensure reliable, low-maintenance operation for agriculture and food industries. Lastly, centrifugal pumps can be adapted for cold weather with proper precautions, serving various purposes from water supply to construction.

Understanding these options and their unique benefits ensures that Alaskan industries can maintain efficient and reliable operations despite the challenging conditions.

Maximizing pump life reduces capital costs, prevents downtime, and improves efficiency. Key strategies include proper installation, routine inspections, lubrication, vibration monitoring, and timely seal or bearing replacement. Operator training is also essential. Educated personnel can monitor pump performance, identify early warning signs, and report issues before they escalate. At IPA907, we help clients develop customized maintenance schedules and operator training programs to extend pump longevity. By investing in these strategies, industrial facilities can ensure reliable pump operation, reduce maintenance expenses, and achieve long-term operational success.

Municipal water and wastewater systems rely on pumps for clean water distribution and sewage management. Pumps must operate reliably under varying flow rates, handle corrosive liquids, and run continuously. Regular maintenance is critical to prevent service interruptions. IPA907 provides preventative maintenance, emergency repairs, and installation of new pumps for municipal clients. Our technicians understand the unique regulatory, safety, and operational requirements of municipal water systems, ensuring compliance while maintaining reliability. From water treatment plants to wastewater facilities, IPA907 keeps communities supplied with safe and consistent water services through expert pump solutions.

Agricultural operations depend heavily on reliable pump systems for irrigation, water supply, and nutrient distribution. Pumps must handle high volumes, fluctuating flow rates, and exposure to outdoor environments. Centrifugal pumps are commonly used for irrigation, while submersible pumps provide reliable water supply in wells and reservoirs. Positive displacement pumps are used for transferring fertilizers, chemicals, and viscous liquids. Proper selection, installation, and maintenance prevent downtime during critical planting and harvest periods. IPA907 offers full agricultural pump solutions, including installation, service, and preventative maintenance programs. By partnering with experienced technicians, farms can maintain consistent operations, reduce energy costs, and ensure optimal crop production.

Industrial operations often require different pump types to meet specific fluid handling needs. Centrifugal pumps and positive displacement pumps are the most common, and selecting the right type is critical for performance. Centrifugal pumps move fluids by converting rotational energy into velocity, making them ideal for high-flow, low-viscosity applications like water transfer, irrigation, or cooling systems. Positive displacement pumps move a fixed volume per cycle, making them suitable for viscous liquids, chemical dosing, and precise fluid transfer. Choosing between these pumps requires considering factors such as fluid viscosity, required flow rate, system pressure, and operational environment. Misapplication can lead to energy waste, premature wear, or failure. IPA907 provides expert guidance on pump selection, ensuring clients choose the correct type for their specific industrial needs.

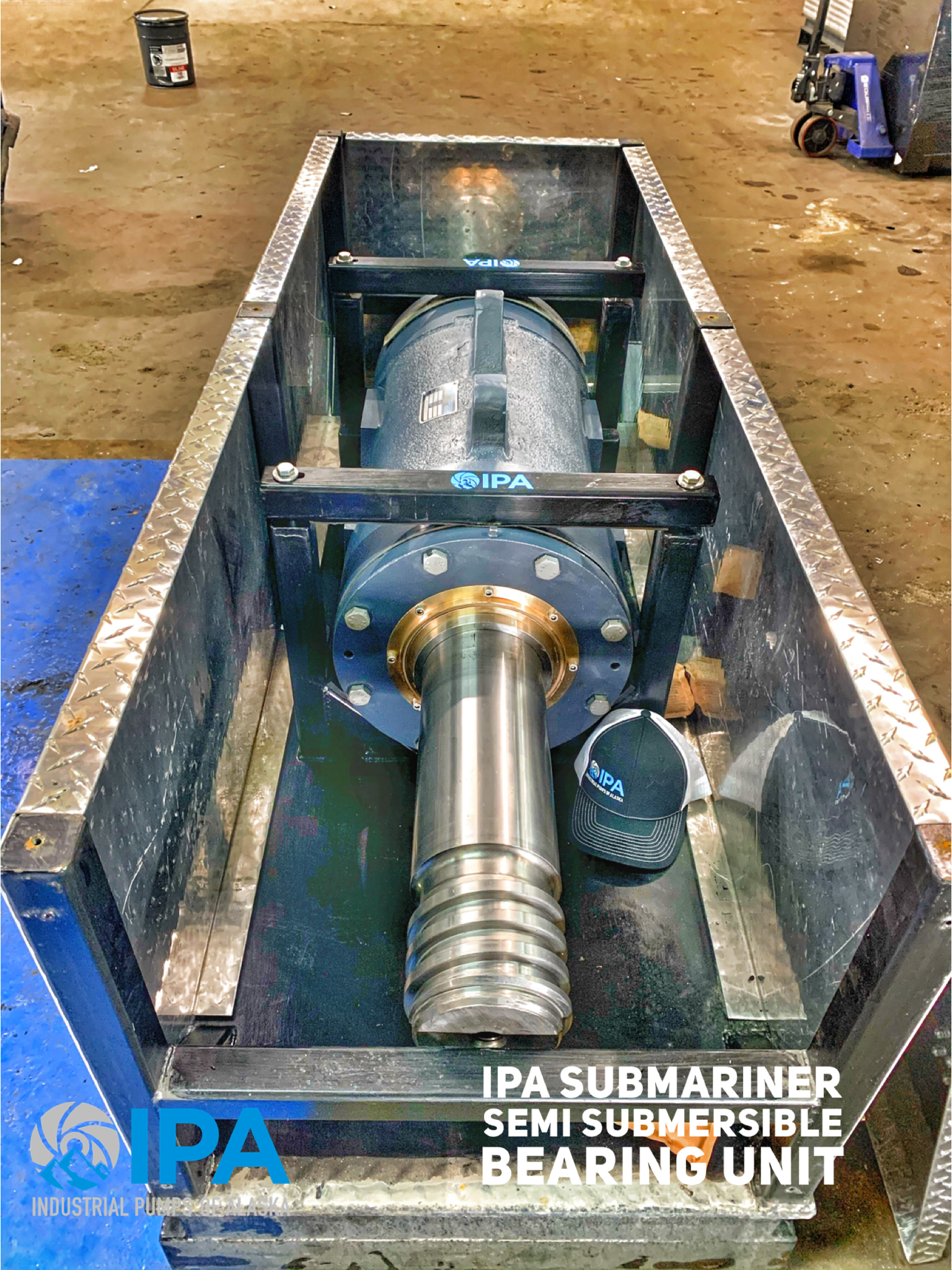

Using genuine pump parts is essential for maintaining performance, reliability, and longevity. Industrial pumps are designed with precision components—improper or low-quality replacements can lead to premature failure, reduced efficiency, and increased maintenance costs. Critical components like seals, bearings, impellers, and gaskets must meet manufacturer specifications. Aftermarket parts may not offer the same durability or tolerances, leading to leaks, vibration, or even catastrophic failure. By using genuine parts, facilities ensure that pumps operate as intended, maintaining optimal flow, pressure, and energy efficiency. IPA907 provides a full range of genuine replacement parts for various pump types, including centrifugal, positive displacement, submersible, and chemical pumps. Our technicians also advise on parts maintenance schedules, helping clients plan replacements proactively rather than reactively. Investing in high-quality parts reduces long-term expenses, avoids unplanned downtime, and ensures reliable operation across all industrial applications, from municipal water systems to mining and manufacturing operations.

Unexpected pump failures can halt production, disrupt water systems, or impact critical infrastructure. Having access to emergency pump repair services is essential for industries that rely on continuous operations. At IPA907, we offer rapid-response repair services designed to minimize downtime. Our technicians are trained to handle a variety of pumps, from centrifugal and submersible to positive displacement and chemical transfer pumps. We carry essential parts for common repairs, enabling us to address most issues on-site. For more complex problems, our in-shop facilities provide complete pump overhauls with fast turnaround times. Industries such as mining, municipal water systems, and manufacturing particularly benefit from emergency pump support. In mining operations, a failed slurry pump can stop production lines, causing significant financial losses. Municipal water and wastewater systems depend on pumps for safe and reliable operation—any failure could disrupt essential services. IPA907’s rapid-response teams ensure these critical systems stay online and functional. Preventing downtime through emergency support requires expertise, planning, and a well-stocked inventory of replacement parts. With IPA907, industrial facilities have peace of mind knowing that expert help is available whenever and wherever it’s needed in the western states.

Industrial pumps are robust machines, but like any mechanical system, they can develop problems over time. Understanding common pump issues and knowing how to troubleshoot them is essential for minimizing downtime and maintaining efficiency. Some of the most frequent pump problems include cavitation, leaks, unusual vibration, reduced flow, and motor failures. Cavitation occurs when vapor bubbles form inside the pump due to low inlet pressure, causing damage to impellers and reduced performance. Leaks are often caused by worn seals or gaskets and can result in fluid loss, contamination, or environmental hazards. Vibration may indicate misalignment, worn bearings, or an unbalanced impeller. Reduced flow can stem from clogged suction lines, air entrainment, or impeller wear. Motor failures may arise from electrical issues, overloads, or inadequate lubrication. Effective troubleshooting starts with thorough observation. Monitoring pump performance, recording operating parameters, and noting unusual noises or vibrations can help identify the root cause. At IPA907, our technicians use advanced diagnostic tools to analyze pump behavior, including vibration analysis, thermal imaging, and flow testing. Once the problem is identified, proper corrective action can be taken, whether that’s adjusting system conditions, replacing worn parts, or performing a complete pump overhaul. Regular training and documentation also make troubleshooting faster and more accurate, allowing facilities to maintain productivity with minimal downtime. By investing in proper troubleshooting processes, industrial facilities can prevent minor issues from escalating, reduce repair costs, and ensure reliable pump performance across all applications. 4. Upgrading Your Pump System for Better Efficiency Many industrial facilities operate with aging pump systems that consume more energy and require frequent repairs. Upgrading to modern, high-efficiency pumps can dramatically improve operational performance and reduce long-term costs. Energy-efficient pumps, such as those with variable frequency drives (VFDs), can adjust flow rates based on system demand, reducing electricity consumption and minimizing mechanical wear. Modern impeller designs and high-quality materials improve flow efficiency while extending service life. Additionally, upgraded pumps often feature better seals, bearings, and control systems, which reduce maintenance frequency and operational risks. At IPA907, we provide comprehensive pump assessments to determine whether an upgrade is necessary. Our technicians evaluate current pump performance, operational costs, and industry requirements to recommend the most effective solution. From installation to commissioning, we handle the entire process, ensuring minimal disruption to your operations. Upgrading pumps is not just about energy savings—it also improves reliability. Newer pumps are less prone to breakdowns and often have enhanced monitoring capabilities, allowing for predictive maintenance and performance tracking. Industries such as water treatment, mining, agriculture, and manufacturing see immediate benefits from pump modernization. By investing in pump upgrades, facilities can achieve better efficiency, lower operating costs, and increased system reliability, making it a smart and sustainable choice for long-term industrial success.

Preventative maintenance is essential for any industrial facility that relies on pumps to keep operations running smoothly. Pumps are the heart of many industrial systems, whether in manufacturing, water treatment, agriculture, or mining. Neglecting maintenance can lead to unexpected failures, costly downtime, and even damage to other system components. A solid preventative maintenance program includes scheduled inspections, lubrication, seal and gasket checks, and vibration analysis. These steps allow technicians to detect early signs of wear or mechanical issues before they escalate. For example, vibration analysis can reveal misalignment or imbalance in the pump shaft, which could eventually cause catastrophic failure if left unaddressed. Similarly, monitoring seals and gaskets prevents leaks that could contaminate the pumped fluid or damage the surrounding equipment. Predictive monitoring tools have become increasingly important in modern pump maintenance. By tracking vibration, temperature, and flow metrics, facilities can predict when maintenance is needed, rather than reacting after a failure occurs. This approach reduces unplanned downtime and helps organizations plan resources more efficiently. At IPA907, our preventative maintenance programs are customized for each client. We consider the pump type, fluid handled, operating conditions, and industry requirements to ensure maximum reliability. From centrifugals to positive displacement pumps, we create schedules that reduce operational risk while extending pump life. Investing in proactive care is far more cost-effective than emergency repairs, especially in industries where downtime directly impacts production and revenue. By taking preventative maintenance seriously, facilities can enjoy consistent pump performance, reduced energy consumption, and long-term savings, making it a vital strategy for industrial success.

Selecting the correct pump is crucial for operational efficiency. Industrial pumps vary by type, including centrifugal, positive displacement, submersible, and specialty chemical pumps. Each has specific applications: centrifugal pumps are ideal for high-volume water movement, while positive displacement pumps handle viscous fluids. Factors to consider include flow rate, pressure, fluid type, temperature, and installation environment. Partnering with experienced providers like IPA907 ensures you select a pump that meets your facility’s needs while minimizing maintenance and energy costs. Additionally, proper sizing and installation prevent premature wear, saving time and money.

Industrial pumps are the silent workhorses powering some of the most critical sectors of the United States economy. From oil and gas production to water treatment and manufacturing, these essential machines ensure that fluids, from crude oil to wastewater, are moved efficiently and reliably. At Industrial Pumps of Alaska, we recognize the importance of these systems not just for our state but for the entire nation. The Backbone of Key Industries Several industries rely heavily on industrial pumps, making them indispensable to the U.S. economy: Oil and Gas: The oil and gas sector is a cornerstone of the U.S. economy, contributing significantly to GDP and employment. Pumps are essential in extracting crude oil, refining it into usable products, and transporting it through pipelines. Without industrial pumps, the energy sector would grind to a halt, affecting everything from transportation to manufacturing. Water and Wastewater Management: Clean water is a basic necessity, and pumps are crucial in both supplying water to homes and industries and in treating wastewater. Municipalities across the country depend on industrial pumps to maintain public health and safety by ensuring that clean water is available and wastewater is effectively managed. Manufacturing: From food processing to chemical production, the manufacturing sector relies on pumps to handle everything from raw materials to finished products. Pumps keep production lines running smoothly, impacting everything from the food we eat to the electronics we use daily. Agriculture: Agriculture is another critical sector that depends on industrial pumps. These pumps are used for irrigation, ensuring that crops receive the necessary water to grow, and for the transportation of fertilizers and pesticides. The efficiency of modern farming practices, and thus the stability of the nation's food supply, hinges on reliable pump systems. Mining: The mining industry is crucial for the extraction of minerals and resources needed for various sectors, including construction, technology, and manufacturing. Pumps play a key role in dewatering mines, transporting slurry, and processing ores, making them vital to the industry’s operations. Economic Impact The industries mentioned above are not just important for their output; they are also significant employers. Millions of Americans work in jobs related to oil and gas, manufacturing, agriculture, and more. The smooth operation of industrial pumps ensures that these industries continue to thrive, providing stable employment and supporting communities across the nation. In addition to employment, these industries generate substantial tax revenue, which funds public services and infrastructure. The U.S. economy is deeply interconnected, and the success of one sector often impacts others. For example, the availability of oil and gas affects transportation costs, which in turn influences the cost of goods and services across the economy. Innovation and Sustainability At Industrial Pumps of Alaska, we understand the importance of staying at the forefront of technological advancements. As industries evolve, so too must the pumps that serve them. Energy efficiency, sustainability, and reliability are key factors driving innovation in the pump industry. For example, as the country shifts towards more sustainable energy sources, such as wind and solar, the need for specialized pumps in these areas is growing. Furthermore, the emphasis on reducing water waste and improving water management systems is driving demand for advanced pump technologies that minimize environmental impact. Industrial pumps are the unsung heroes of the U.S. economy. They keep essential industries running, support millions of jobs, and contribute to the nation’s economic stability. At Industrial Pumps of Alaska, we take pride in being a part of this vital industry, ensuring that the pumps we provide are reliable, efficient, and ready to meet the demands of a dynamic economy. Whether it's in the frozen tundras of Alaska or the bustling factories of the Midwest, industrial pumps are at the heart of America's economic engine..